Pre-Engineered Building Services in Multan | ACCO Engineering Pre-Engineered Building Services in Multan – ACCO…

Types of Pre Engineered Buildings in Pakistan: Industrial, Commercial & Residential

🏗️ Introduction to ACCO Engineering

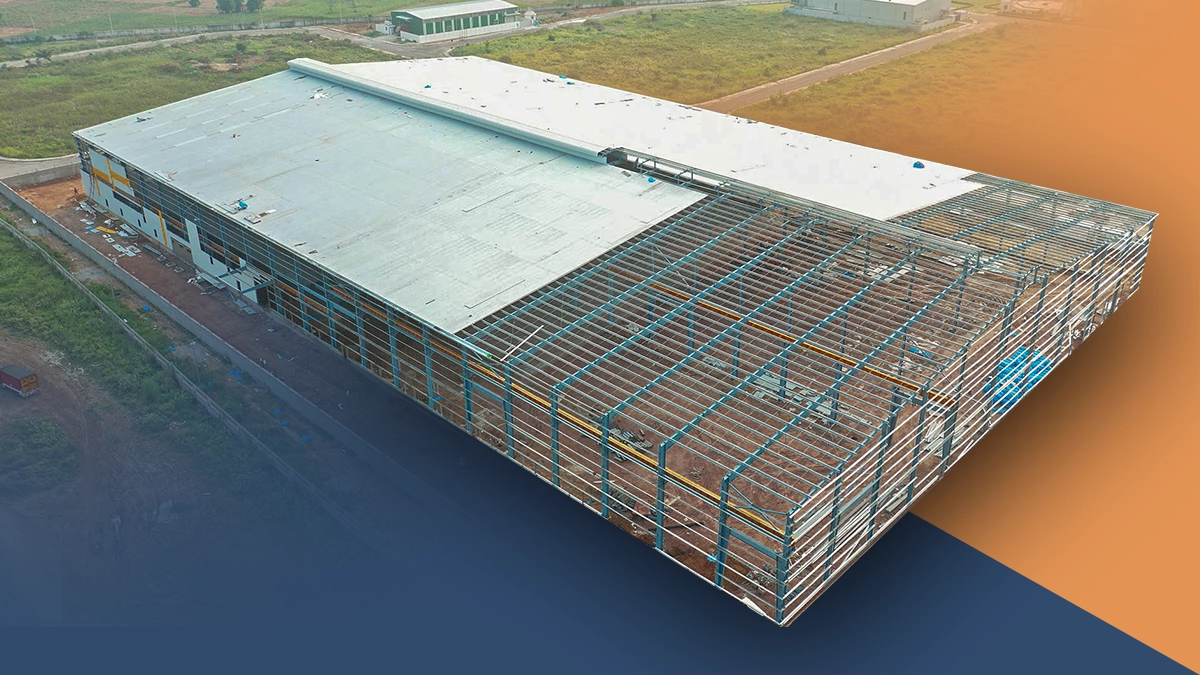

ACCO Engineering is a premier construction and engineering company in Pakistan, specializing in Pre Engineered Buildings (PEBs), industrial sheds, commercial complexes, and residential steel structures. With extensive experience, ACCO Engineering has delivered projects across Karachi, Lahore, and major cities of Pakistan, providing high-quality, durable, and cost-effective PEB solutions.

Our expertise includes:

- Design, fabrication, and installation of industrial, commercial, and residential PEBs

- Turnkey construction solutions tailored to client needs

- Compliance with local and international engineering standards

- Efficient project management to ensure timely delivery

Website: www.accoengineering.com

Email: info@acco.com.pk

🏭 Topic Introduction: Why Pre Engineered Buildings Matter in Pakistan

Pre Engineered Buildings (PEBs) are increasingly popular in Pakistan due to their cost-efficiency, fast construction, and flexibility. Unlike conventional construction, PEBs use prefabricated steel components designed for specific applications, which allows for:

- Faster project completion

- Lower material waste

- Reduced labor requirements

- Easy scalability and future expansion

In cities like Karachi and Lahore, where industrialization, commercial development, and urban housing demands are growing rapidly, choosing the right type of PEB is crucial for businesses and property developers. Understanding the various types of PEBs helps investors and builders make informed decisions.

📐 Types of Pre Engineered Buildings

PEBs can be broadly classified into three categories based on their application: Industrial, Commercial, and Residential. Each type has its own design requirements, benefits, and considerations.

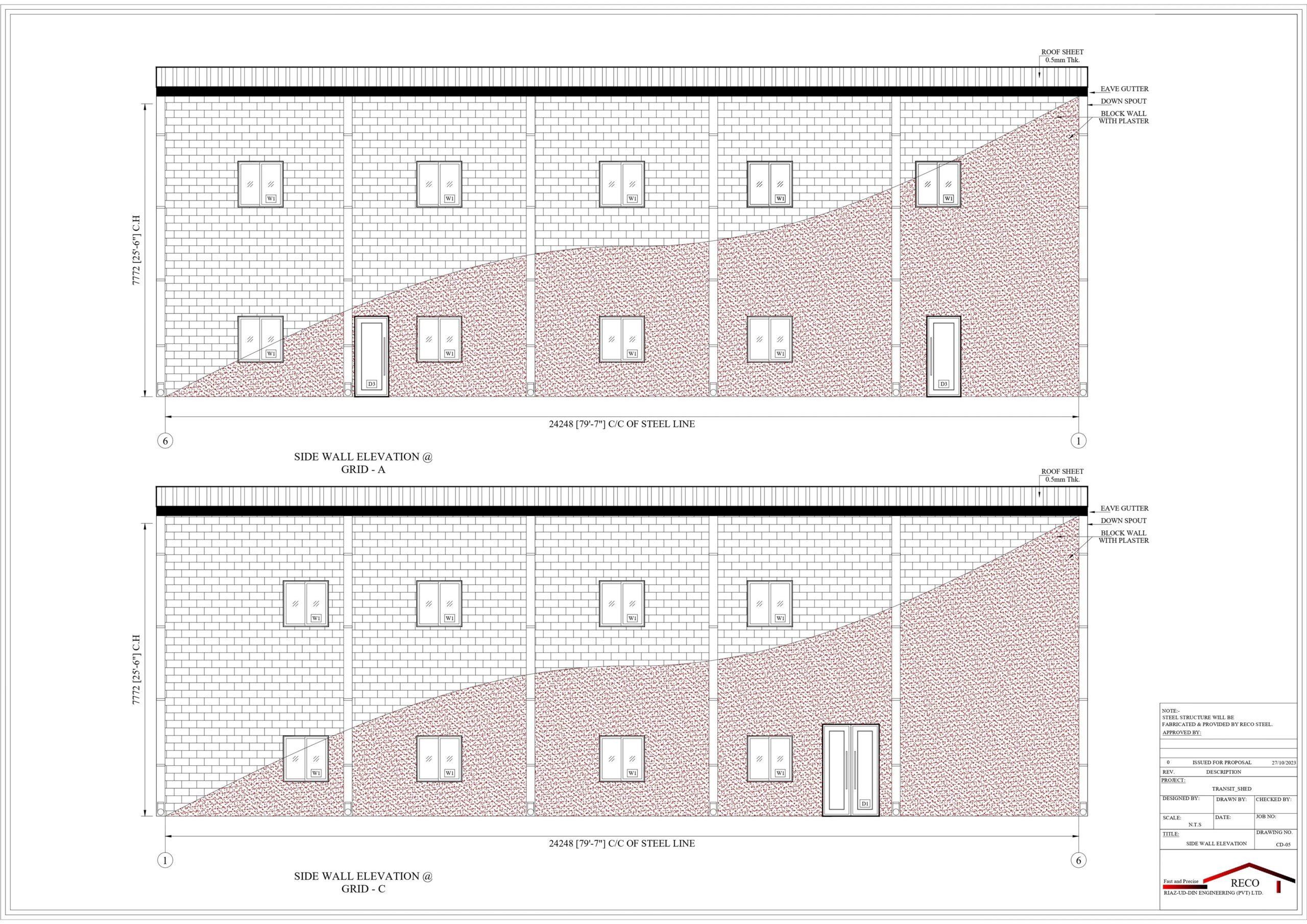

1️⃣ Industrial Pre Engineered Buildings

Industrial PEBs are widely used for factories, warehouses, workshops, and manufacturing units.

Key Features:

- Large clear spans for machinery and storage

- High load-bearing capacity

- Customizable roof slopes and truss designs

- Integrated MEP (mechanical, electrical, plumbing) systems

Common Uses:

- Textile and garment factories

- Warehousing and storage facilities

- Automotive workshops

- Food processing plants

Advantages:

- Fast construction reduces downtime

- Durable steel structures withstand heavy loads

- Easy integration with industrial equipment

Example: A 20,000 sq. ft. industrial shed in Karachi completed in 10 weeks with crane-ready infrastructure and ventilation systems.

2️⃣ Commercial Pre Engineered Buildings

Commercial PEBs are used for shopping malls, offices, showrooms, and retail outlets.

Key Features:

- Flexible layout for shops and offices

- Large column-free areas for better customer experience

- Aesthetic façade options

- Fire-resistant steel and cladding

Common Uses:

- Retail plazas and commercial centers

- Corporate offices and IT parks

- Showrooms and exhibition halls

Advantages:

- Faster ROI due to reduced construction time

- Low maintenance with long-term durability

- Flexibility to design multi-level structures

Trends in Pakistan: Many developers in Lahore and Karachi are adopting PEB for commercial projects due to urban space constraints and modern aesthetics.

3️⃣ Residential Pre Engineered Buildings

Residential PEBs are customizable steel structures suitable for villas, townhouses, and gated community homes.

Key Features:

- Lightweight and earthquake-resistant structure

- Faster construction than traditional brick-and-mortar homes

- Flexible design to accommodate multiple floors

- Integration with smart home technologies

Advantages:

- Shorter construction timelines

- Lower long-term maintenance costs

- Modern design flexibility

Example: A 3,000 sq. ft. PEB villa in Lahore completed in 12 weeks, featuring modern interiors, energy-efficient insulation, and earthquake-resistant design.

⚙️ How to Choose the Right PEB Type

Choosing the correct PEB involves evaluating project type, budget, location, and long-term requirements.

Key Considerations:

- Project Purpose: Industrial, commercial, or residential

- Building Size: Clear span, height, and total area

- Load Requirements: Roof, wind, and seismic load calculations

- Design Flexibility: Expansion possibilities and layout customization

- Material Quality: Steel grade, coating, and cladding type

- Project Budget: Balance between quality and cost efficiency

Tip: Consult experienced providers like ACCO Engineering to ensure structural compliance and project feasibility.

📊 Comparison Table: Industrial vs Commercial vs Residential PEBs

| Feature | Industrial PEB | Commercial PEB | Residential PEB |

|---|---|---|---|

| Typical Use | Factories, Warehouses | Offices, Retail | Villas, Townhouses |

| Span | Large (30–60m) | Medium (20–40m) | Small to Medium (10–25m) |

| Load Bearing | Very High | Medium | Low to Medium |

| Construction Speed | Fast | Moderate | Fast |

| Customization | Equipment Layout | Layout & Aesthetics | Interior & Exterior Design |

| Maintenance | Low | Low | Low |

🔍 Pros & Cons of Pre Engineered Buildings

✅ Advantages

- Rapid construction timelines ⏱️

- Cost-effective material usage 💰

- Flexibility in design and expansion 🏗️

- High durability and low maintenance 🔧

- Lightweight and environmentally friendly 🌱

❌ Disadvantages

- Initial design and fabrication costs can be high ⚠️

- Requires experienced installation team 👷

- Limited traditional architectural aesthetics for some residential projects 🏘️

❓ Frequently Asked Questions (FAQs)

❓ What is a Pre Engineered Building (PEB)?

A PEB is a structural steel building designed, fabricated, and erected using prefabricated steel components tailored to specific applications.

❓ What types of PEBs are available in Pakistan?

There are industrial, commercial, and residential PEBs, each suited for specific project requirements.

❓ Why are PEBs popular in Karachi and Lahore?

Due to rapid urbanization, industrial growth, and the need for fast, cost-effective construction, PEBs are widely adopted.

❓ How long does it take to build a PEB?

Depending on size and type, a medium-scale PEB typically takes 8–12 weeks, from design to completion.

❓ Does ACCO Engineering provide turnkey PEB solutions?

Yes, ACCO Engineering offers complete turnkey services, including design, fabrication, installation, and project handover.

🔗 Internal Links

- House Construction in DHA Lahore

- Commercial Plaza Builders Lahore

- Turnkey Construction Services in Pakistan

🌐 External Authority References

- Pakistan Engineering Council

- DAWN News – Industrial Construction Trends

- ArchDaily – Pre Engineered Building Case Studies

🏁 Final Verdict: Why Choose ACCO Engineering for Your PEB

Selecting the right type of Pre Engineered Building ensures:

- Faster project completion

- Long-term durability and low maintenance

- Compliance with local and international standards

- Cost-effective and scalable solutions

ACCO Engineering delivers industrial, commercial, and residential PEBs tailored to your needs in Karachi, Lahore, and across Pakistan, ensuring quality, efficiency, and reliability.

📞 Call to Action – Build Your PEB with ACCO Engineering

🏭 Looking for industrial, commercial, or residential PEBs in Pakistan?

📐 Contact ACCO Engineering today for a FREE consultation!

- 📞 Phone / WhatsApp: 0322-8000190

- 🌐 Website: www.accoengineering.com

- 📩 Email: info@acco.com.pk

This Post Has 0 Comments