Introduction to ACCO Engineering 🏗️ ACCO Engineering is a leading engineering and construction company in…

Logistics Warehousing Solutions Using PEB Technology | ACCO Engineering

Introduction to ACCO Engineering

At ACCO Engineering, we specialize in modern construction and engineering solutions for residential, commercial, and industrial sectors across Pakistan. Based in Lahore, our expertise includes pre-engineered buildings (PEBs), steel structures, turnkey construction, and industrial facility design.

With years of experience, ACCO Engineering has successfully delivered projects for warehouses, manufacturing plants, commercial plazas, and logistics facilities, ensuring timely delivery, high-quality standards, and long-lasting durability.

When it comes to logistics and warehousing, efficiency, flexibility, and speed are critical—qualities perfectly achieved through PEB technology.

Introduction to PEB Warehousing Solutions

Logistics warehouses are the backbone of supply chains, ensuring the smooth flow of goods and inventory. In Pakistan, with the growth of e-commerce, manufacturing, and FMCG industries, efficient and scalable warehouse solutions are more important than ever.

PEB (Pre-Engineered Building) technology allows warehouses to be constructed faster, cost-effectively, and with superior structural integrity. These steel buildings are modular, durable, and easily expandable, making them ideal for logistics and distribution centers.

Complete Details of Logistics Warehousing Solutions Using PEB

What is a PEB Warehouse?

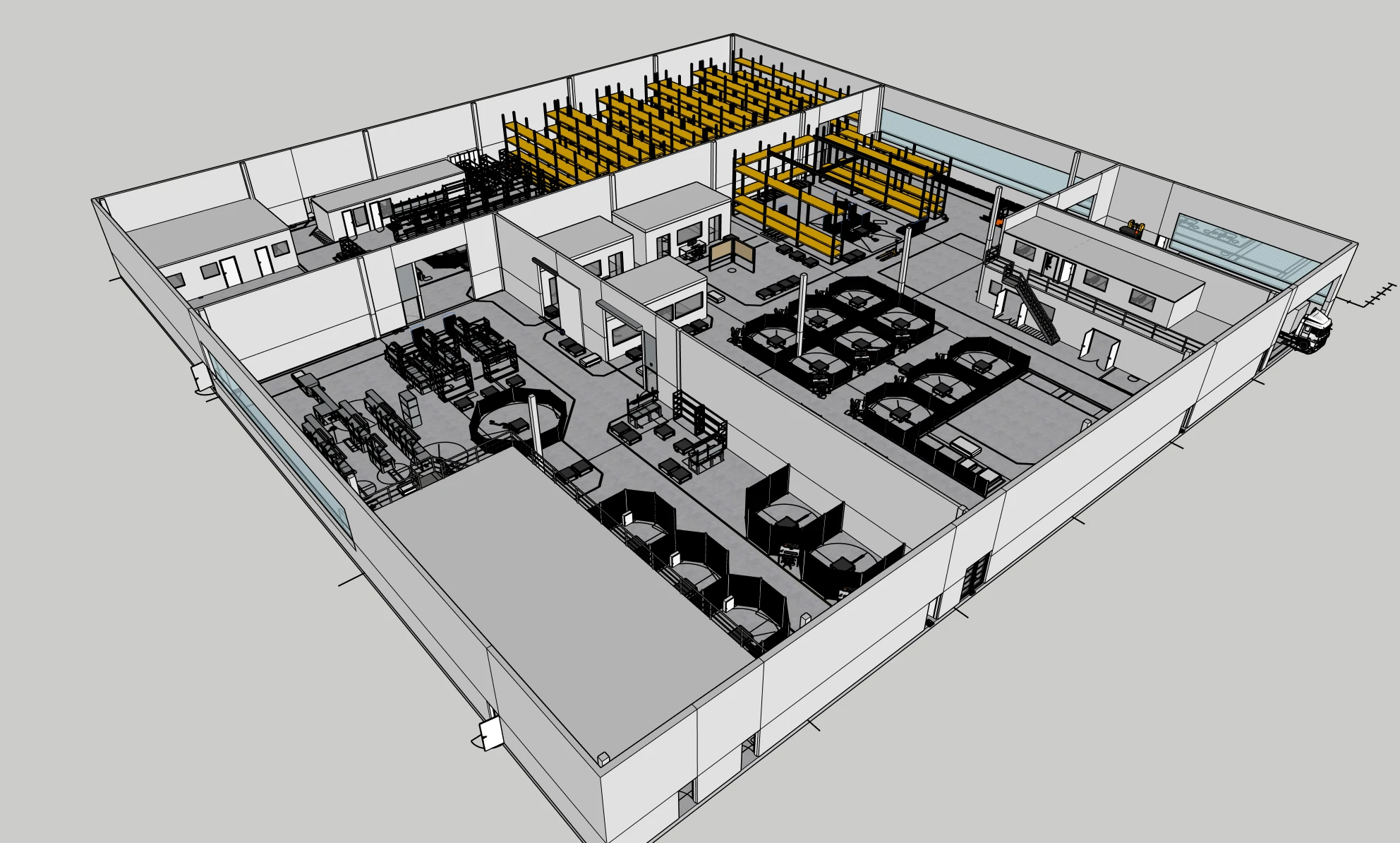

A PEB warehouse is a pre-fabricated steel structure designed for industrial storage and logistics operations. Key components include:

- Primary frames: Columns and beams that support the building

- Secondary members: Purlins, girts, and bracings for structural stability

- Cladding: Insulated or galvanized steel panels for walls and roofs

- Accessories: Skylights, doors, loading docks, and ventilation systems

Features of PEB Warehouses

Durable & Long-Lasting

- High-grade steel prevents corrosion, termites, and wear

- Engineered to withstand heavy storage loads and industrial equipment

Flexible Design Options

- Clear-span widths up to 100 meters

- Single or multi-span layouts for large inventories

- Modular design allows for future expansion

Cost-Effective Construction

- Reduced construction time compared to RCC warehouses

- Lower labor and material costs

- Minimal maintenance requirements

Energy-Efficient & Eco-Friendly

- Insulated panels maintain internal temperature

- Skylights and ventilation systems reduce electricity use

Construction Process of PEB Warehouses

- Design & Engineering – Customized plans to match storage needs

- Fabrication – Steel components manufactured in controlled factory settings

- Transportation – Safe delivery to the construction site

- On-Site Assembly – Quick installation using bolted connections

- Finishing & Accessories – Doors, windows, loading bays, and insulation

Comparison Table: PEB Warehouses vs Conventional Warehouses

| Feature | PEB Warehouse | Conventional Warehouse |

|---|---|---|

| Construction Time | 30–50% faster | Longer due to on-site work |

| Cost | 20–40% lower | Higher material & labor costs |

| Design Flexibility | High (customizable spans) | Limited |

| Durability | High (engineered for load) | Moderate |

| Maintenance | Low | Moderate to high |

Pros and Cons of PEB Warehouses

✅ Benefits

- Faster construction: Save months on project timelines

- Cost-efficient: Lower initial investment and operational costs

- Expandable: Modular design allows easy future extensions

- Durable & reliable: Withstands heavy storage loads and weather conditions

- Low maintenance: Minimal upkeep compared to conventional warehouses

⚠️ Disadvantages

- Requires expert engineering design

- Steel treatment needed in highly humid or coastal areas

- Aesthetic limitations for office-style interiors (can be enhanced with finishes)

Frequently Asked Questions (FAQs)

1. Are PEB warehouses suitable for large-scale logistics operations?

Yes, they can accommodate heavy storage loads, high racking systems, and large inventory efficiently.

2. How quickly can a PEB warehouse be constructed?

Construction usually takes 3–6 months, depending on size and customization.

3. Can PEB warehouses be expanded later?

Absolutely. The modular design allows easy future extensions without major reconstruction.

4. Are PEB warehouses cost-effective in Pakistan?

Yes. They reduce labor, material, and maintenance costs while providing faster project completion.

5. What maintenance is required for a PEB warehouse?

Minimal maintenance includes regular inspection for rust, cleaning gutters, and checking insulation panels.

Final Verdict

PEB technology revolutionizes logistics warehousing in Pakistan. These warehouses combine speed, durability, flexibility, and cost efficiency, making them ideal for manufacturing, FMCG, e-commerce, and distribution centers.

For reliable turnkey PEB warehouse solutions, trust ACCO Engineering. We deliver fully customized, high-quality warehouses that meet your logistics and storage needs efficiently.

Internal Links

External References

- Construction Industry Pakistan

- ArchDaily: Industrial Building Designs

- DAWN News: Pakistan Logistics Sector

Call to Action

Contact ACCO Engineering today for a free consultation!

🌐 Website: Accoengineering.com

📧 Email: Info@acco.com.pk

📞 Phone: 0322-8000190

💬 WhatsApp: Click to chat

Contact Page

This Post Has 0 Comments