Introduction to ACCO Engineering 🏗️ ACCO Engineering is a leading engineering and construction company in…

A–Z Guide to Steel PEB Shed Manufacturing in Pakistan

By ACCO Engineering — Pakistan’s Leading PEB & Industrial Solutions Company

⭐ Introduction to ACCO Engineering

ACCO Engineering is Pakistan’s trusted name in Pre-Engineered Buildings (PEB), industrial steel structures, sports & leisure solutions, and turnkey construction services.

Located in Lahore, the company has delivered hundreds of PEB warehouses, production units, logistics centers, factory sheds, and industrial facilities across Pakistan.

With decades of combined engineering experience, ACCO Engineering specializes in:

- Steel PEB Shed Manufacturing

- Industrial Layout Planning

- Turnkey Industrial Construction

- Structural Engineering

- PEB Design, Fabrication & Installation

- Industrial Warehouse Solutions

When it comes to high-performance industrial steel buildings, ACCO Engineering is known for quality, commitment, and cutting-edge engineering that maximizes industrial efficiency.

🚀 Introduction to the Topic

This blog presents a complete A–Z Guide to Steel PEB Shed Manufacturing in Pakistan, ideal for factory owners, industrial planners, contractors, and investors.

The focus is on the keyword “PEB Buildings for Industrial Efficiency”, explaining how modern PEB structures significantly improve production flow, energy efficiency, safety, and operational performance.

Why is it important in Pakistan?

- Industries are upgrading old RCC structures to fast, economical, and durable PEB buildings.

- Industrial growth, exports, and manufacturing demand faster expansion.

- PEB sheds offer 40–60% time savings, essential in Pakistan’s fast-paced industrial environment.

- Rising material costs make PEB more economical than conventional buildings.

Let’s dive into the complete A–Z process.

🏗️ A–Z Guide to Steel PEB Shed Manufacturing in Pakistan

This guide breaks down every step involved in designing, engineering, fabricating, and installing a PEB building.

🔤 A — Assessment of Client Needs

PEB manufacturing starts with a detailed requirement discussion:

- Type of Industry (FMCG, Pharma, Textile, Auto, Cold Storage, Logistics, etc.)

- Required Shed Size (Length, Width, Height)

- Clear Height & Crane Requirements

- Ventilation & Temperature Control

- Fire & Safety Codes

- Future Expansion Needs

This ensures the PEB structure supports maximum production efficiency.

🔤 B — Budget Planning & BOQ Preparation

A transparent Bill of Quantities (BOQ) includes:

- Steel weight & material cost

- Fabrication charges

- Installation & labor cost

- Roofing & wall sheeting

- Accessories (vents, skylights, insulation)

- Civil works (if required)

PEB solutions are 30–40% more economical than RCC, making them ideal for factories and warehouses.

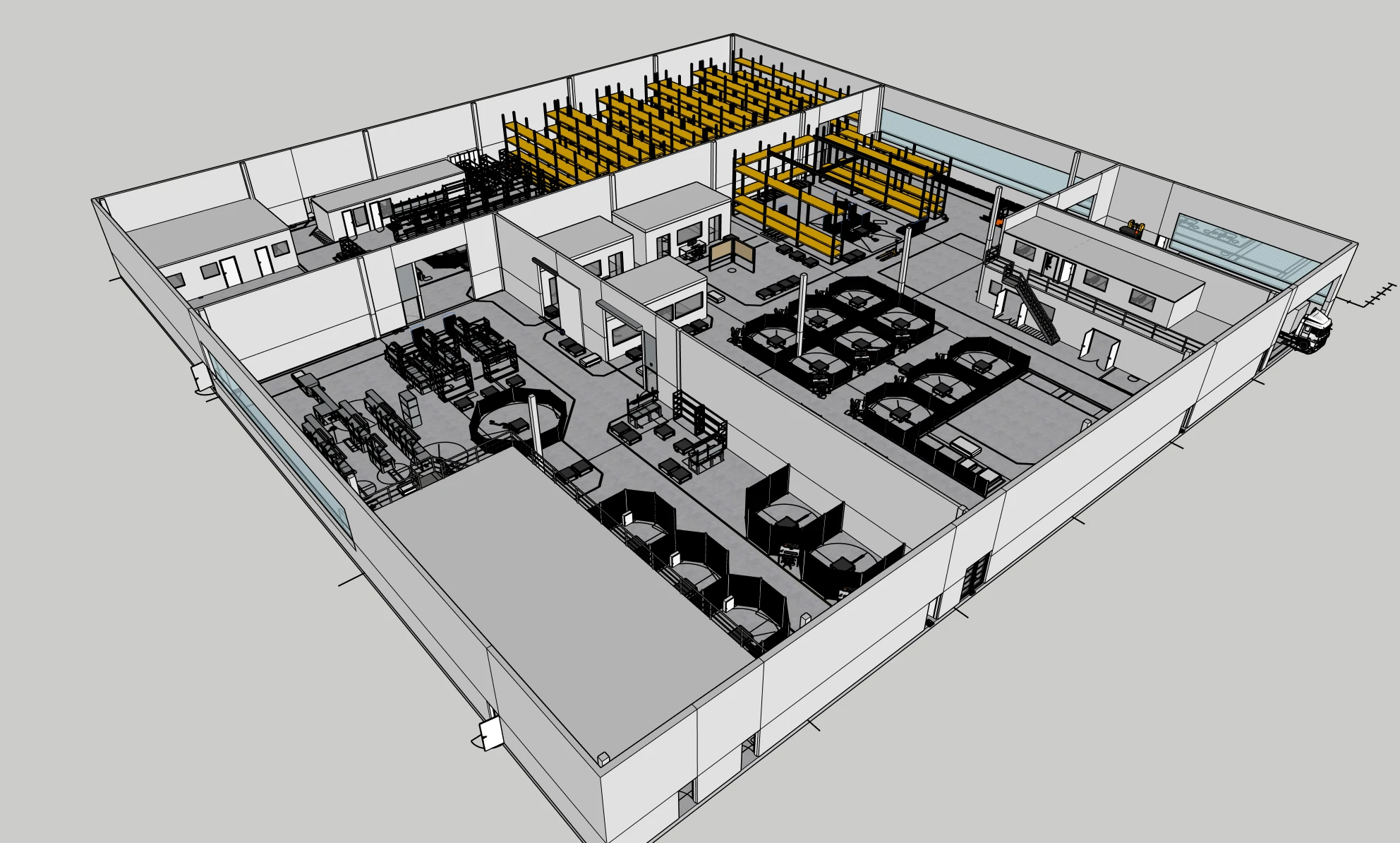

🔤 C — Conceptual Design

ACCO Engineering prepares:

- 2D & 3D Concept Models

- Structural Frame Layout

- Effective Column Grid Planning

- Clearance Height Optimization

- Bay Spacing

- Architectural Elevations

Concept design ensures maximum operational smoothness.

🔤 D — Detailed Engineering

This is where engineering precision matters most:

- Structural analysis

- Load calculations (wind, dead, live)

- Frame optimization

- Weld design

- Anchor bolt planning

- Foundation load distribution

This guarantees long-term durability and safety.

🔤 E — Estimation & Steel Weight Calculation

Weight calculations determine:

- Steel quantity

- Cost accuracy

- Structural safety

- Material specifications

Accuracy ensures no hidden cost during project execution.

🔤 F — Fabrication

Fabrication includes:

- CNC plasma cutting

- Beam welding

- Drilling & punching

- Assemble & fit testing

- Sand blasting

- Epoxy or zinc coating

ACCO Engineering uses automated fabrication methods for precision.

🔤 G — Galvanization & Coating

Steel protection options:

- Hot-dip galvanization

- Epoxy paint

- Zinc primers

- Weather-resistant coatings

This ensures a long lifespan even in harsh industrial environments.

🔤 H — Handling & Transport

Transport includes:

- Protective wrapping

- Road-safe loading

- Damage-free shipping

- Secure site unloading

Proper handling reduces delays and material loss.

🔤 I — Installation & On-Site Erection

On-site erection includes:

- Anchor bolt fixing

- Column erection

- Rafter installation

- Purlins & girts

- Roof & wall sheeting

- Ventilation accessories

- Insulation

- Finishing details

PEB erection is 45–60% faster than traditional construction.

🔤 J — Joint Inspection

Both teams inspect:

- Bolt torque

- Welding quality

- Structural alignment

- Panel finishing

- Accessories

- Insulation work

This ensures complete structure compliance.

🔤 K — Key Performance Indicators (KPIs)

PEB buildings improve:

- Production output

- Logistics flow

- Machinery layout

- Material movement

- Energy performance

- Employee comfort

🔤 L — Lifecycle Cost Savings

PEB = minimum maintenance.

Cost savings include:

- No structural repairs

- No dampness or cracks

- Lower energy usage

- Fast expansion capability

- Long building life (50+ years)

🔤 M — Material Standards

Common materials used:

- ASTM A36 structural steel

- A572 Grade 50 high-strength steel

- Galvanized (GI) sheets

- PUF insulated panels

- Polycarbonate skylights

🔤 N — Noise & Heat Insulation

Industries require proper insulation:

- Glass wool

- Rockwool

- PU/PIR insulation

- Double-layer roof systems

Helps maintain temperature, reduce electricity bills, and improve comfort.

🔤 O — Operational Efficiency (Main Keyword)

⭐ How PEB Buildings Improve Industrial Efficiency

Using the focus keyword:

PEB Buildings for Industrial Efficiency offer:

- Better production flow

- Clear open spans for machinery

- Faster material handling

- Enhanced safety

- Superior ventilation

- Lower energy consumption

- Quick expansion for future growth

This is why Pakistan’s industries are rapidly shifting from RCC to PEB.

🔤 P — Project Management

ACCO Engineering ensures:

- Daily progress monitoring

- Quality checks

- Fast execution

- Safety compliance

- Timeline management

🔤 Q — Quality Assurance

Quality tests include:

- Welding inspection

- Bolt testing

- Steel grade verification

- Structural alignment

- Sheeting quality checks

🔤 R — Risk Management

Includes:

- Fire safety design

- Emergency exits

- Load safety

- Wind-resistant engineering

- Lightning protection

🔤 S — Site Planning

Industrial efficiency depends on layout:

- Production line flow

- Raw material movement

- Finished goods loading

- Waste management

- Employee pathways

Good site planning = faster operations.

🔤 T — Turnkey PEB Solutions

ACCO Engineering delivers complete PEB solutions:

- Planning

- Engineering

- Fabrication

- Installation

- Civil works (if required)

- Complete commissioning

🔤 U — Utility Planning

Includes:

- Electrical layout

- Lighting plan

- HVAC ducting

- Drainage system

- Fire hydrant layout

🔤 V — Ventilation & Lighting

Options include:

- Ridge ventilators

- Turbo ventilators

- Louvers

- Skylights

- Polycarbonate sheets

These help reduce energy usage and improve working conditions.

🔤 W — Warehouse Optimization

A good warehouse plan includes:

- Racking layout

- Forklift movement

- Docking area

- Mezzanine floors

- Packing zones

PEB warehouses allow excellent interior flexibility.

🔤 X — X-Factor: Speed

The biggest advantage of PEB?

Speed.

Industries can start operations 60% earlier compared to RCC.

🔤 Y — Yield Optimization

PEB structures optimize:

- Storage capacity

- Production area

- Machinery layout

- Loading/unloading flow

🔤 Z — Zero Maintenance

PEB sheds require:

- No plaster

- No cracks

- No leakage

- No deformation

This makes them ideal for long-term industrial use.

⚖️ Pros & Cons of PEB Buildings

✅ Pros

- Fast construction

- Cost-effective

- Long-lasting

- High strength-to-weight ratio

- Ideal for large spans

- Fire-safe design

- Easy to expand

- Low maintenance

- Modern appearance

❌ Cons

- Needs professional engineering

- Requires precise installation

- Limited architectural detailing compared to RCC

- Transport for large members may require planning

❓ Frequently Asked Questions (FAQs)

1. How long does it take to build a PEB shed?

Typically 45–90 days depending on size.

2. Are PEB structures safe?

Yes, they are engineered as per international safety standards.

3. What industries use PEB?

All — textile, FMCG, pharma, packaging, logistics, auto, cold storage.

4. Is PEB cheaper than RCC?

Yes, up to 40% cost savings.

5. Can PEB sheds be insulated?

Yes, using glass wool, rockwool, or PU panels.

🧩 Internal Links (for your website)

You can add:

- Industrial Construction Services

- PEB Warehouse Solutions

- Sports & Leisure Solutions

- Turnkey Industrial Projects Pakistan

🌍 External Links (High Authority Sources)

- ArchDaily (construction insights)

- Dawn Business (industry updates)

- PEC Pakistan (engineering standards)

- Construction.gov.pk (regulations)

🏁 Conclusion

Steel PEB Shed Manufacturing is the future of Pakistan’s industrial development. With unmatched speed, cost efficiency, durability, and operational benefits, PEB buildings drastically improve industrial efficiency.

ACCO Engineering ensures world-class PEB solutions with advanced engineering, international standards, and fast project delivery.

📞 Contact ACCO Engineering

🌐 Website: www.accoengineering.com

📧 Email: info@accoengineering.com

🔖 20 SEO Tags (comma-separated)

PEB Buildings for Industrial Efficiency, Steel PEB Manufacturing Pakistan, PEB Warehouse Construction, Industrial PEB Design Pakistan, Steel Structure Shed Lahore, PEB Fabrication Services, Pre Engineered Buildings Pakistan, Industrial Shed Manufacturer, Warehouse Construction Pakistan, PEB Factory Sheds, Steel Building Manufacturer Lahore, Industrial Steel Structures Pakistan, PEB Design and Build Services, Turnkey Industrial Construction Pakistan, Metal Building Solutions Pakistan, PEB Warehouse Design, Steel Workshop Construction, Industrial Steel Building Pakistan, ACCO Engineering PEB Solutions, PEB Construction Company Pakistan

This Post Has 0 Comments