Modern Pre-Engineered Industrial Structures Islamabad | ACCO Modern Pre-Engineered Industrial Structures in Islamabad | ACCO…

PEB Solutions for Textile Industry | ACCO Engineering Faisalabad

PEB Solutions for Textile Industry | ACCO Engineering Faisalabad

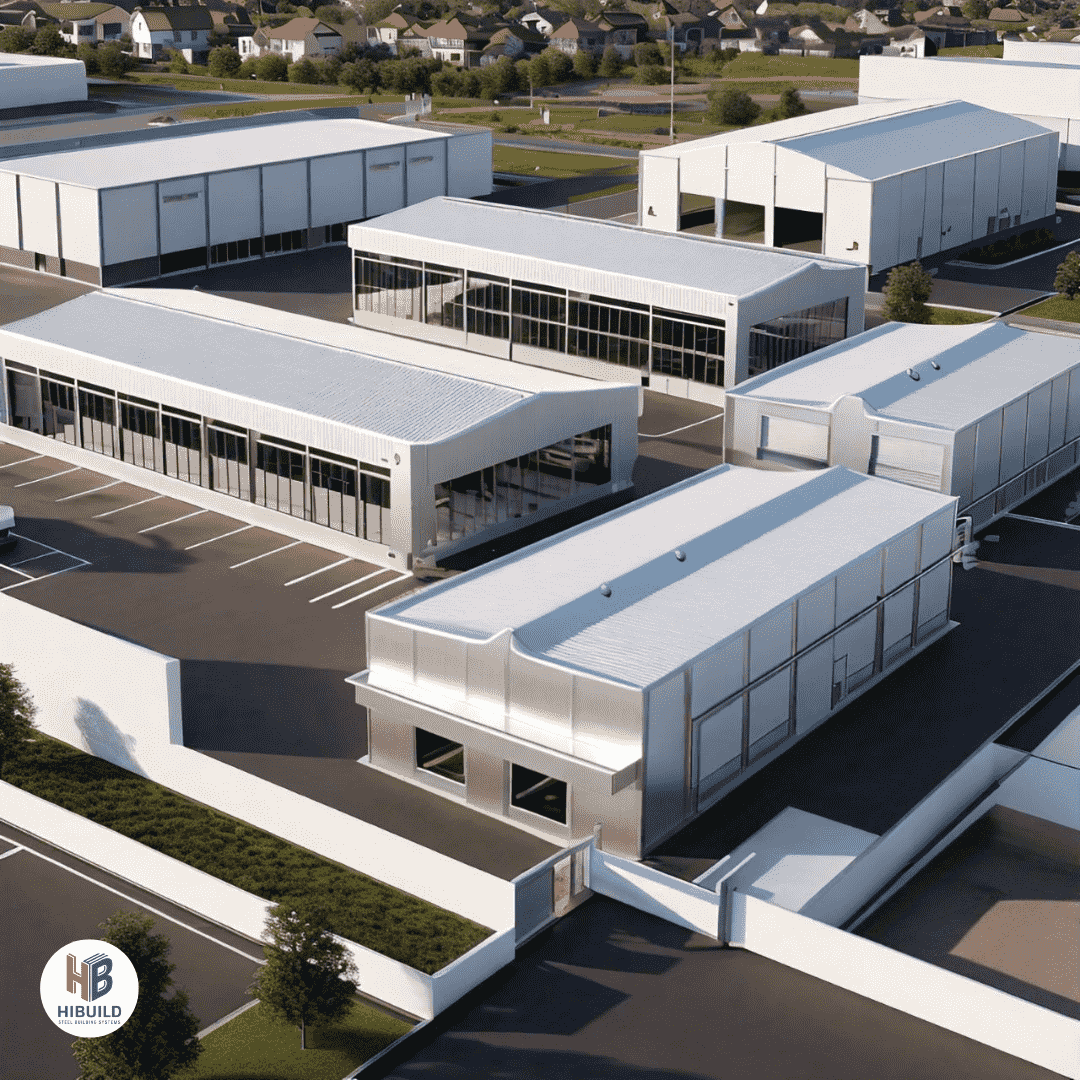

Introduction to ACCO Engineering – Experts in Industrial Construction

ACCO Engineering is a leading engineering and construction company in Pakistan, renowned for delivering industrial buildings, pre-engineered steel structures (PEB), and turnkey solutions.

With years of experience in textile, manufacturing, and logistics industries, ACCO Engineering has established a reputation for quality, timely project delivery, and cost-effective solutions.

Based in Lahore, the company serves Faisalabad, Karachi, Sialkot, Multan, and other industrial hubs, specializing in:

- Industrial sheds and warehouses

- Pre-engineered steel buildings (PEB)

- Factory expansions and modular structures

- Cold storage and food processing facilities

- Turnkey industrial construction

ACCO Engineering ensures structural integrity, operational efficiency, and compliance with local building codes, making it a trusted partner for Pakistan’s industrial sector.

Topic Introduction: PEB Solutions for Textile Industry in Faisalabad

Faisalabad, famously known as Pakistan’s Manchester, is the heart of the textile industry, housing hundreds of spinning mills, garment factories, and processing units.

The textile industry demands high-performance infrastructure that can support:

- Large machinery and looms

- Heavy-duty storage

- Efficient workflow and material handling

Traditional RCC factories are often costly, time-consuming, and inflexible. Pre-Engineered Buildings (PEB) offer faster construction, scalability, and column-free spaces, ideal for modern textile operations.

ACCO Engineering provides custom PEB solutions in Faisalabad, tailored to the unique requirements of textile factories, helping businesses increase productivity, reduce operational costs, and future-proof their facilities.

Understanding PEB Solutions for Textile Industry

What Are Pre-Engineered Buildings (PEB)?

Pre-Engineered Buildings (PEB) are industrial structures designed with prefabricated steel components, manufactured off-site and assembled on location.

Key features of PEB for textile factories include:

- High-strength steel frames to support heavy machinery

- Column-free interiors for efficient space utilization

- Customizable roof and wall panels for insulation and ventilation

- Modular design allowing future expansion

Benefits over conventional construction include faster timelines, cost efficiency, and scalability for growing textile operations.

Components of PEB Textile Factories

1. Primary Steel Structure

- Columns and rafters designed for heavy loads

- Supports overhead cranes and machinery

2. Secondary Steel Members

- Purlins, girts, and bracings

- Provides roof and wall stability

3. Roofing & Wall Cladding

- Pre-painted or Aluzinc steel sheets

- Optional insulation panels for temperature control

4. Ventilation & Lighting

- Ridge ventilators, turbo vents, and skylights

- Reduces energy consumption and improves air quality

5. Accessories & Utilities

- Industrial doors and rolling shutters

- Mezzanine floors for offices or storage

- Crane rails and heavy-duty platforms

Why PEB Is Ideal for Textile Industry in Faisalabad

- Large Clear Spans: Ideal for textile machinery layout

- Fast Installation: Reduces downtime for factory operations

- Scalability: Easy expansion as business grows

- Durability: Long-lasting steel structures with minimal maintenance

- Energy Efficiency: Insulated panels and natural lighting reduce operational costs

Construction Process of PEB Textile Factories

- Design & Engineering: Customized layout using CAD software and load calculations for machinery.

- Fabrication: Steel members prefabricated off-site for precision and quality.

- Site Preparation: Foundation work according to structural loads and soil condition.

- Assembly & Erection: Steel frames assembled with cranes; roofing, cladding, and utilities installed.

- Finishing & Handover: Painting, insulation, and final inspection. Ready-to-operate factory delivered on schedule.

Cost Considerations for PEB Textile Factories

| Building Type | Approx. Cost (PKR/sq.ft) |

|---|---|

| Standard Textile Shed | 4,500 – 6,500 |

| Insulated Textile Factory | 6,000 – 8,500 |

| Cold Storage Textile Facility | 7,500 – 10,000 |

Costs vary based on building size, insulation, roof height, and accessories. ACCO Engineering provides free project consultations and detailed BOQs.

Pros & Cons of PEB for Textile Industry

✅ Pros

- Fast construction (6–10 weeks)

- Cost-effective for medium to large factories

- Column-free spans for machinery layout

- Modular design allows expansion

- Low maintenance with anti-corrosion steel

❌ Cons

- Requires skilled engineering and fabrication

- Poor design/fabrication affects durability

- Limited architectural aesthetics compared to RCC

Current Trends in Textile Industry Factories

- Automation-friendly PEB layouts

- Energy-efficient insulated panels

- Integration of smart lighting and ventilation systems

- Modular factories for future scalability

- Compliance with local safety and building regulations

Frequently Asked Questions (FAQs)

1. How long does it take to construct a PEB textile factory?

Typically 6–10 weeks, depending on size and complexity.

2. Can PEB buildings handle heavy textile machinery?

Yes. High-strength steel frames support cranes, looms, and large machines.

3. Are PEB textile factories cost-effective?

Yes. Faster construction and reduced material waste make them more economical than RCC factories.

4. Can I expand my PEB factory in the future?

Absolutely. Modular design allows horizontal or vertical expansion.

5. Does ACCO Engineering provide turnkey solutions?

Yes. From design and fabrication to erection and handover, we offer complete solutions.

Internal Links for SEO

External References

Final Verdict: Why Choose PEB for Textile Factories

PEB solutions are fast, scalable, and cost-effective, making them ideal for textile factories in Faisalabad.

ACCO Engineering provides:

- Expert PEB design and construction

- Turnkey solutions for textile production, storage, and processing

- Durable, low-maintenance steel structures

- Flexible and modular layouts for future expansion

Investing in PEB factories ensures efficient operations, reduced costs, and long-term growth in Faisalabad’s competitive textile sector.

Call to Action – Contact ACCO Engineering

📞 Phone / WhatsApp: 0322-1000190

📧 Email: info@accoengineering.com

🌐 Website: www.accoengineering.com

📍 Office: Office #2, 3rd Floor, Bigcity Plaza, Gulberg-III, Lahore

👉 Contact ACCO today for a free consultation on PEB solutions for the textile industry in Faisalabad!

This Post Has 0 Comments