Modern Pre-Engineered Industrial Structures Islamabad | ACCO Modern Pre-Engineered Industrial Structures in Islamabad | ACCO…

Smart Warehouse Planning with Pre-Engineered Buildings in Pakistan | ACCO Engineering

Introduction to ACCO Engineering 🏗️

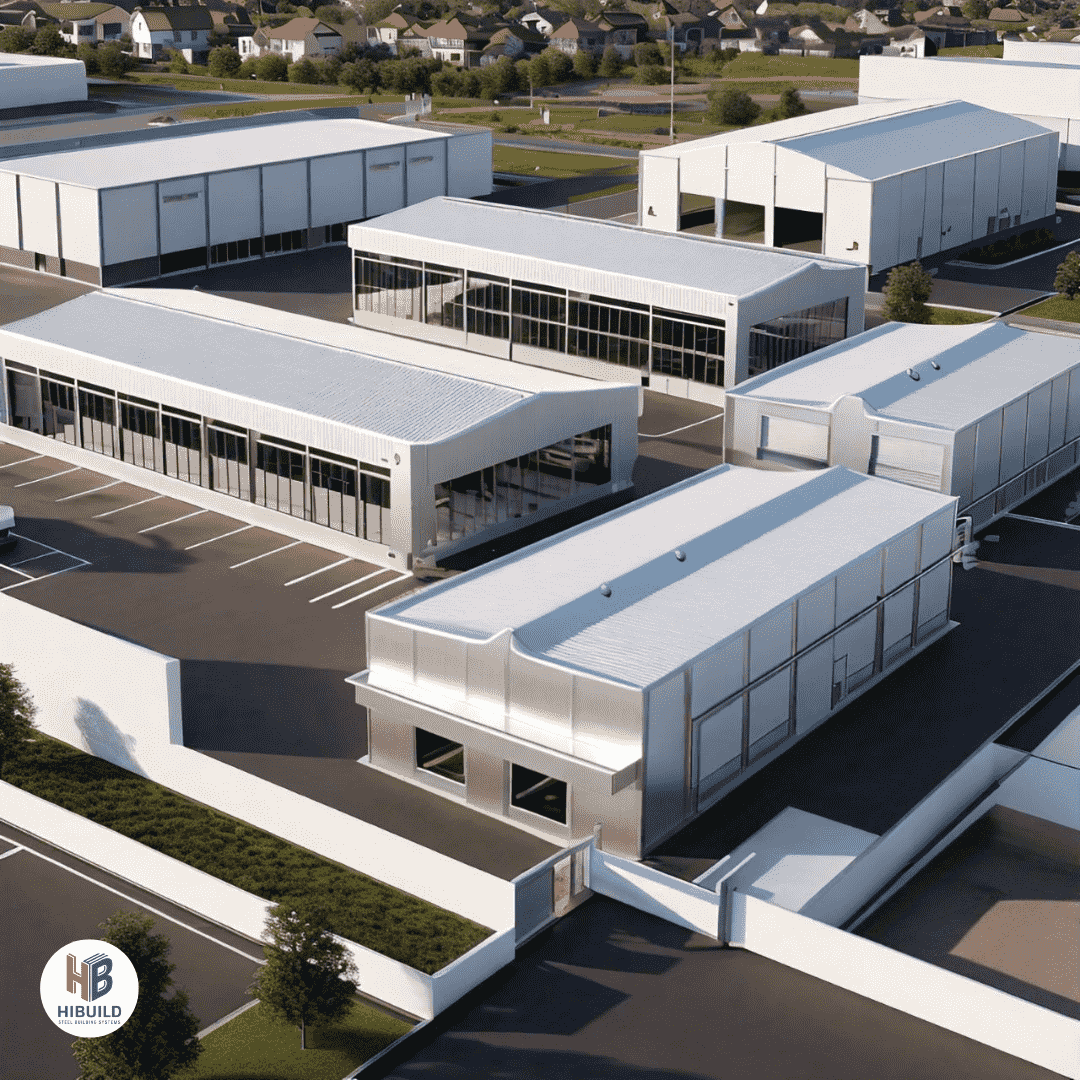

ACCO Engineering is a leading engineering and construction company in Pakistan, specializing in pre-engineered buildings (PEBs), warehouses, industrial units, and modern infrastructure solutions. With years of expertise, ACCO Engineering has established itself as a trusted partner for businesses seeking efficient, cost-effective, and sustainable construction solutions.

Based in Lahore, ACCO Engineering serves clients across Pakistan, offering tailored services for warehouse planning, industrial projects, and commercial buildings. Our team combines technical expertise and modern engineering practices to deliver high-quality results.

Visit our website for more: www.accoengineering.com

What is Smart Warehouse Planning? 🏭

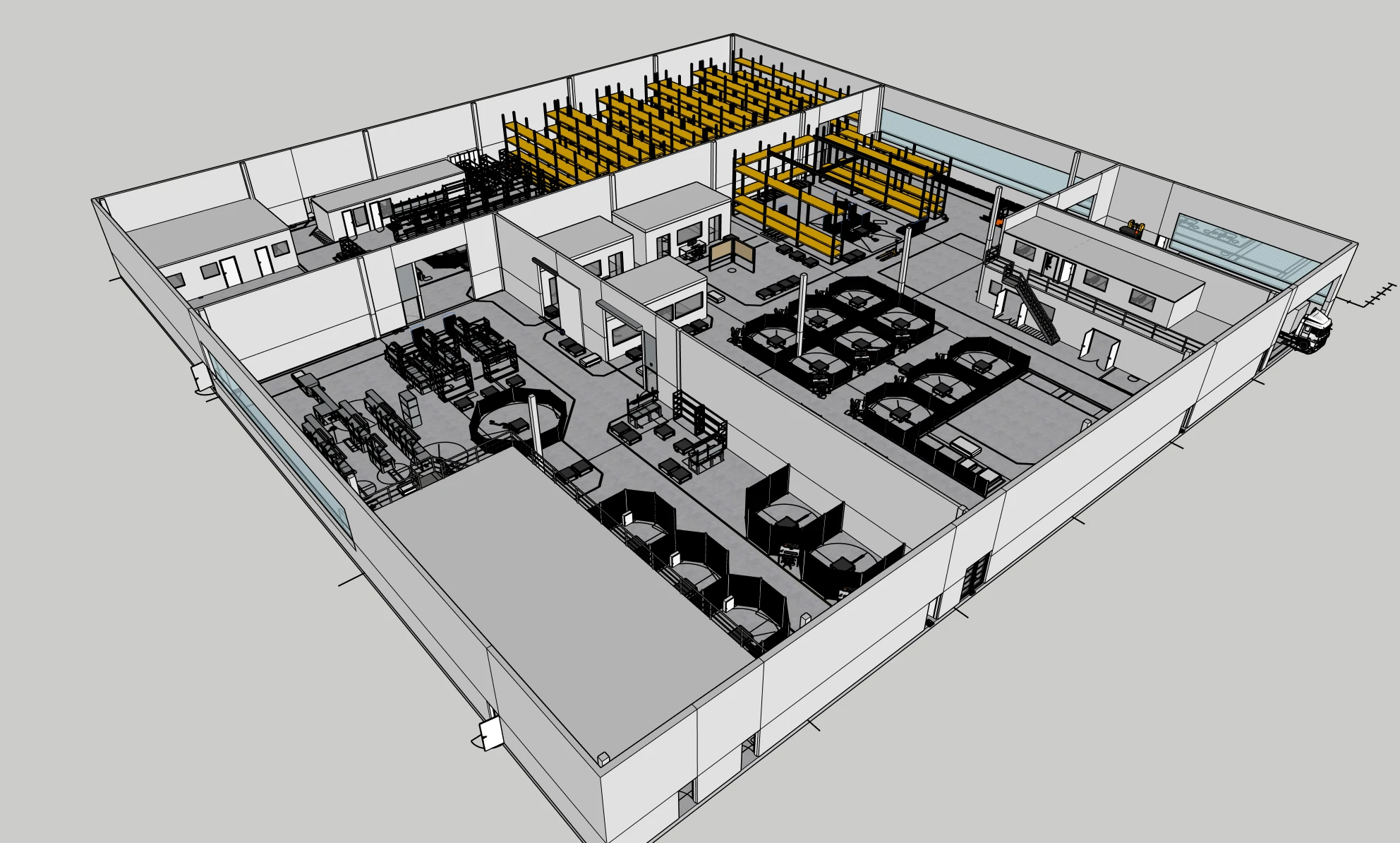

Smart warehouse planning refers to the strategic design and optimization of warehouse spaces to enhance storage efficiency, workflow, and inventory management. Modern warehouses are technology-driven hubs that streamline operations and reduce operational costs.

In Pakistan, the rapid growth of e-commerce, logistics, and manufacturing has created a pressing demand for smart warehouse solutions. Companies are increasingly opting for pre-engineered buildings (PEBs) due to their speed of construction, cost-effectiveness, and long-term durability.

Why Pre-Engineered Buildings (PEBs) Are Ideal for Warehouses ⚙️

Pre-engineered buildings are steel structures fabricated off-site and assembled on-site, offering unmatched flexibility and durability.

Key Features of PEB Warehouses:

- Quick Construction: PEB warehouses can be built up to 50% faster than traditional concrete buildings.

- Cost Efficiency: Lower labor and material costs with long-term durability.

- Scalability: Easily expanded or modified as business needs grow.

- Durability: Resistant to extreme weather, heavy loads, and seismic activity.

- Low Maintenance: Minimal upkeep compared to conventional warehouses.

PEB Warehouse Design Options

| Feature | Option 1 | Option 2 | Option 3 |

|---|---|---|---|

| Roof Type | Gable Roof | Single Slope | Sawtooth Roof |

| Wall Material | Galvanized Steel | Insulated Panels | Sandwich Panels |

| Flooring | Concrete | Epoxy Coating | Industrial Tiles |

| Expansion | Modular | Fixed | Flexible |

Tip: Selecting the right PEB design depends on warehouse size, inventory type, and operational workflow.

Steps for Smart Warehouse Planning 📝

1. Assess Your Business Needs

- Determine storage capacity based on inventory types.

- Plan for future expansion and scalability.

- Analyze workflow and loading/unloading processes.

2. Layout Optimization

- Use zoning techniques for receiving, storage, and shipping areas.

- Plan aisles, racks, and shelves for maximum efficiency.

- Integrate automation options like conveyors or robotic picking systems.

3. Material Handling Systems

- Decide on forklifts, pallet jacks, or AGVs (Automated Guided Vehicles).

- Optimize warehouse flow for efficiency and safety.

4. Safety & Compliance

- Include fire safety, emergency exits, and proper ventilation.

- Ensure compliance with Pakistan construction and safety regulations.

- Incorporate eco-friendly solutions like solar panels or rainwater harvesting.

5. Technology Integration

- Implement Warehouse Management Systems (WMS) for inventory tracking.

- Use IoT devices and sensors for real-time monitoring.

- Plan for future technology upgrades in the warehouse.

Advantages of Smart Warehouses with PEBs ✅

- Faster Construction: Complete projects in less time.

- Cost Savings: Reduced capital and operational expenses.

- Scalable Design: Expand or modify as needed.

- Enhanced Workflow: Optimized layout increases productivity.

- Durability & Safety: Steel structures withstand extreme conditions.

Disadvantages ❌

- Initial Design Costs: Requires professional planning.

- Limited Architectural Flexibility: Compared to traditional concrete buildings.

- Steel Maintenance: Periodic anti-corrosion measures required.

Smart Warehouse Trends in Pakistan 📈

- E-commerce Boom: Daraz, Shopify sellers, and online retailers need advanced warehouses.

- Cold Storage Growth: Perishable goods logistics is driving demand.

- Automation: Robotics and AI-driven inventory management are trending.

- Sustainability: Eco-friendly PEBs with insulation and solar options are popular.

FAQs – Smart Warehouse Planning Pakistan ❓

1. What is the cost of a PEB warehouse in Pakistan?

Costs vary by size, design, and materials, typically PKR 2,500–4,500 per sq. ft.

2. How long does construction take?

Usually 3–6 months, depending on the complexity.

3. Can PEB warehouses be expanded?

Yes, PEB warehouses are modular and designed for future expansion.

4. Are PEB warehouses safe in earthquakes or storms?

Yes, they meet structural and safety standards for seismic and wind loads.

5. Is maintenance high for steel warehouses?

No, low maintenance is a key benefit, though occasional anti-corrosion checks are advised.

Why Choose ACCO Engineering for Warehouse Planning? 🏢

ACCO Engineering offers complete warehouse solutions in Pakistan:

- Consultation & Design: Customized layouts based on your business needs.

- PEB Manufacturing: High-quality steel structures fabricated in-house.

- Installation & Commissioning: Timely project completion by expert teams.

- Post-Construction Support: Maintenance, expansions, and upgrades.

Related Services: Industrial PEBs in Lahore, Commercial Warehouse Solutions

External References 🌐

- Construction Industry Pakistan – construction.gov.pk

- DAWN News – Industry & Development

- ArchDaily – Warehouse Architecture Trends

Final Verdict / Conclusion 💡

For businesses in Pakistan, smart warehouse planning with pre-engineered buildings is the most efficient, scalable, and cost-effective solution. Whether you are in logistics, retail, or manufacturing, a PEB warehouse from ACCO Engineering ensures enhanced workflow, durability, and reduced operational costs.

Contact ACCO Engineering today for a free consultation!

📞 Phone/WhatsApp: 0322-8000190 | 🌐 Website: www.accoengineering.com

This Post Has 0 Comments