❄️ Introduction to ACCO Engineering ACCO Engineering is a premier construction and engineering company based…

PEB Structure Fabricators in Pakistan – Quality Steel Construction Experts | ACCO Engineering

🏢 Introduction to ACCO Engineering

ACCO Engineering is Pakistan’s trusted name in Pre-Engineered Building (PEB) design and fabrication, known for delivering modern, efficient, and durable steel construction solutions. Based in Lahore, ACCO Engineering operates nationwide — offering design, fabrication, and turnkey steel building services for industries such as logistics, manufacturing, warehousing, commercial, and sports facilities.

With a reputation built on engineering excellence and reliability, ACCO Engineering’s team of qualified engineers, architects, and fabrication experts ensures every structure is designed for strength, safety, and sustainability.

🔩 What Are PEB Structures?

Pre-Engineered Buildings (PEB) are modern steel structures designed and fabricated off-site, then assembled quickly at the project location.

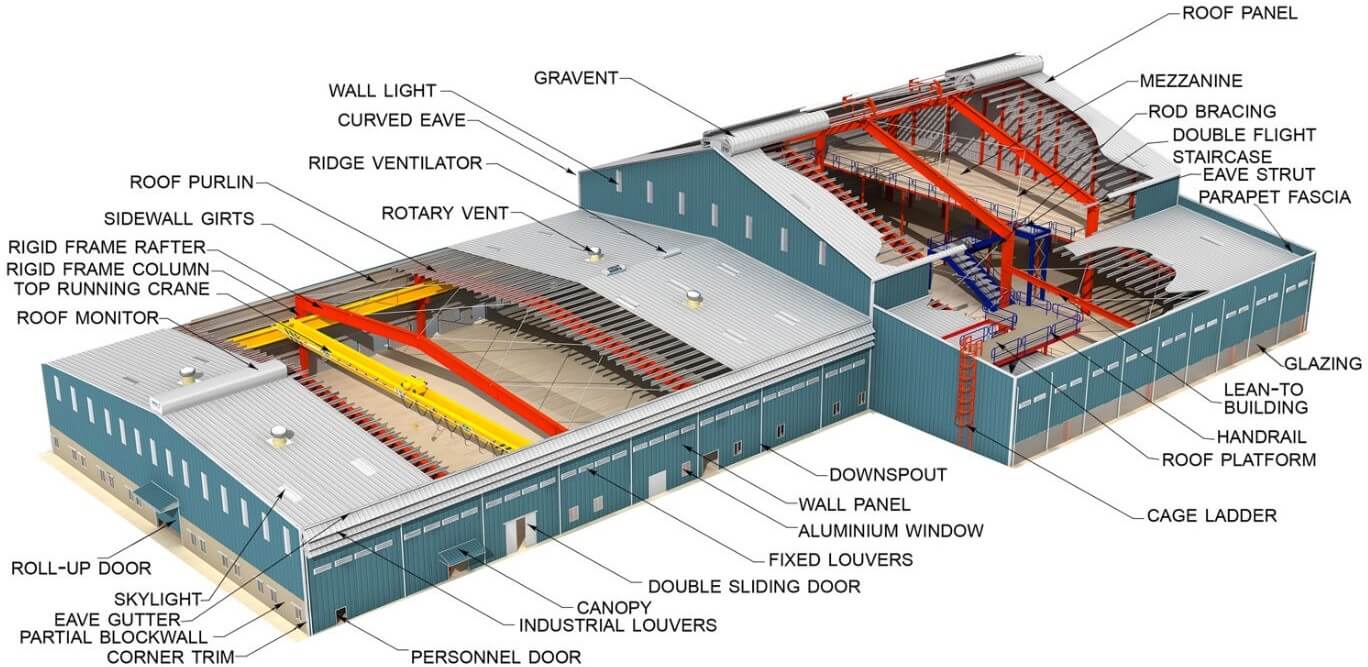

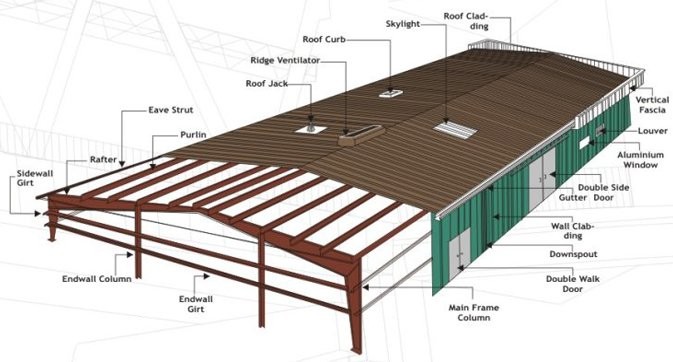

Unlike conventional concrete buildings, PEB systems combine efficiency, flexibility, and cost-effectiveness. They consist of:

- Primary framing (main columns & rafters)

- Secondary members (purlins, girts)

- Roofing & wall cladding

- Fasteners & accessories

PEB systems are ideal for warehouses, factories, showrooms, and industrial plants, where speed, strength, and durability are key.

🇵🇰 Importance of PEB Fabrication in Pakistan

In Pakistan’s fast-developing industrial landscape, time-efficient and budget-friendly construction methods are crucial. Traditional methods often lead to delays, waste, and high costs.

That’s why PEB fabrication is transforming the industry. According to DAWN News, Pakistan’s industrial expansion is increasing demand for smart, quick-build steel structures.

Key Reasons PEB Systems Are Growing in Pakistan:

- 🕒 Faster Project Completion: 50% quicker than conventional methods.

- 💰 Lower Cost: Up to 30% savings on materials and labor.

- 🌱 Sustainability: Recyclable steel, minimal waste.

- ⚙️ High Strength: Engineered for wind, seismic, and live loads.

- 🏭 Versatility: Ideal for factories, logistics hubs, cold storage, and sports arenas.

⚙️ ACCO Engineering – Leading PEB Fabricators in Pakistan

🧱 Our Expertise

ACCO Engineering specializes in end-to-end steel structure services, from conceptual design to on-site erection. Our integrated solutions ensure quality, safety, and timely delivery.

🧰 Core Services:

- PEB Design & Engineering

- Structural analysis and 3D modeling

- Wind, load, and seismic calculations

- Customized architectural layouts

- Fabrication & Manufacturing

- Precision CNC cutting, welding, and painting

- Use of high-grade ASTM & AISI-compliant steel

- Strict quality control & testing

- Erection & Installation

- On-site assembly with skilled manpower

- Bolted connections for flexibility

- Turnkey project management

- Maintenance & Renovation

- Inspection and reinforcement of old steel structures

- Retrofitting and expansion of existing facilities

🏭 Sectors Served by ACCO Engineering

| Sector | Application |

|---|---|

| 🏗️ Industrial Plants | Steel structure manufacturing sheds |

| 📦 Warehouses | Storage & logistics facilities |

| 🏬 Commercial Buildings | Retail spaces, showrooms |

| 🏫 Institutional | Schools, hospitals, & labs |

| 🏟️ Sports Facilities | Indoor arenas & stadiums |

| 🚛 Logistic Hubs | Distribution & transit facilities |

| 🏢 Office Complexes | Modular steel offices |

🧮 Cost-Effectiveness of PEB Fabrication

| Factor | Conventional Building | PEB Structure |

|---|---|---|

| Construction Time | 10–12 months | 4–6 months |

| Cost per sq. ft. | Rs. 3,500–4,000 | Rs. 2,000–2,500 |

| Maintenance | High | Low |

| Design Flexibility | Limited | Excellent |

| Expansion Option | Difficult | Easy |

💡 On average, ACCO Engineering’s PEB projects save clients up to 30% in cost and 50% in time compared to traditional buildings.

🔍 Advantages of Choosing PEB Structures

✅ Advantages

- ⚡ Faster Construction Time

Prefabricated components reduce project duration significantly. - 💰 Economical

Minimal on-site labor, less wastage, and reduced foundation load. - 🏗️ Durable & Reliable

High-strength steel with long life and low maintenance. - 🌍 Eco-Friendly

Recyclable materials support sustainable construction. - 🧩 Design Flexibility

Customizable layouts suitable for any industrial purpose.

❌ Disadvantages

- 🚧 Initial Fabrication Planning Required

Detailed design phase needed before execution. - 🧠 Skilled Labor Demand

Requires experienced engineers and fitters. - 🧾 Transportation Cost

For large structures, delivery logistics can add cost.

🏗️ Why Choose ACCO Engineering for PEB Fabrication?

- 🛠️ In-House Design & Fabrication Facility

- 🧾 Transparent Costing & Documentation

- 👷 Experienced Engineering Team

- 🧩 Custom Design Solutions

- 🏆 Proven Track Record Across Pakistan

- 🌱 Commitment to Sustainability & Quality

🧱 The PEB Construction Process at ACCO Engineering

- Client Consultation & Requirement Analysis

- Conceptual Design & Feasibility

- 3D Structural Modeling & Load Analysis

- Fabrication of Components

- Transportation to Site

- On-Site Assembly & Erection

- Final Inspection & Handover

Each step follows international standards such as AISC, MBMA, and ASTM, ensuring durability and safety.

💼 Notable PEB Projects by ACCO Engineering

- Industrial Warehouse – Lahore

- Pharmaceutical Factory – Faisalabad

- Cold Storage Facility – Karachi

- Sports Arena – Islamabad

- Logistics Hub – Multan

Each project highlights ACCO’s innovation, precision, and timely completion.

📊 Future of PEB Fabrication in Pakistan

With rapid industrialization, the PEB market in Pakistan is expected to grow by 15–20% annually. Government initiatives for industrial zones and export hubs are further boosting demand.

PEB systems are no longer limited to warehouses — they’re now being used for shopping malls, schools, hospitals, and corporate offices.

Source: Pakistan Engineering Council (PEC)

❓ Frequently Asked Questions (FAQs)

1. What is the average cost of PEB construction in Pakistan?

The cost typically ranges between Rs. 2,000 to Rs. 2,500 per sq. ft., depending on design, steel grade, and project location.

2. How long does it take to complete a PEB project?

A medium-sized warehouse (around 20,000 sq. ft.) can be completed in 4–6 months from design to handover.

3. Are PEB structures safe in earthquakes?

Yes. ACCO Engineering designs PEB systems per seismic-resistant standards, ensuring superior stability.

4. Can PEB buildings be expanded later?

Absolutely. They’re modular — you can easily add more bays or sections in the future.

5. Does ACCO Engineering handle turnkey PEB projects?

Yes. ACCO Engineering provides design, fabrication, erection, and after-sale support under a single contract.

🏁 Final Verdict

PEB structures are the future of industrial construction in Pakistan — fast, durable, and sustainable.

With ACCO Engineering, you’re not just hiring fabricators — you’re partnering with steel construction experts who ensure excellence from concept to completion.

Whether you’re building a warehouse, factory, logistics center, or sports facility, ACCO Engineering offers end-to-end PEB solutions designed for performance and long-term value.

📞 Call to Action

Ready to start your PEB project?

👉 Contact ACCO Engineering today for a free consultation!

📍 Office: Bigcity Plaza, Gulberg-III, Lahore

📞 0322 8000190

🌐 www.acco.com.pk

📧 info@acco.com.pk

This Post Has 0 Comments