Modern Pre-Engineered Industrial Structures Islamabad | ACCO Modern Pre-Engineered Industrial Structures in Islamabad | ACCO…

Why Choose Pre-Engineered Buildings in Pakistan – Complete Guide | ACCO Engineering

🏢 Introduction to ACCO Engineering

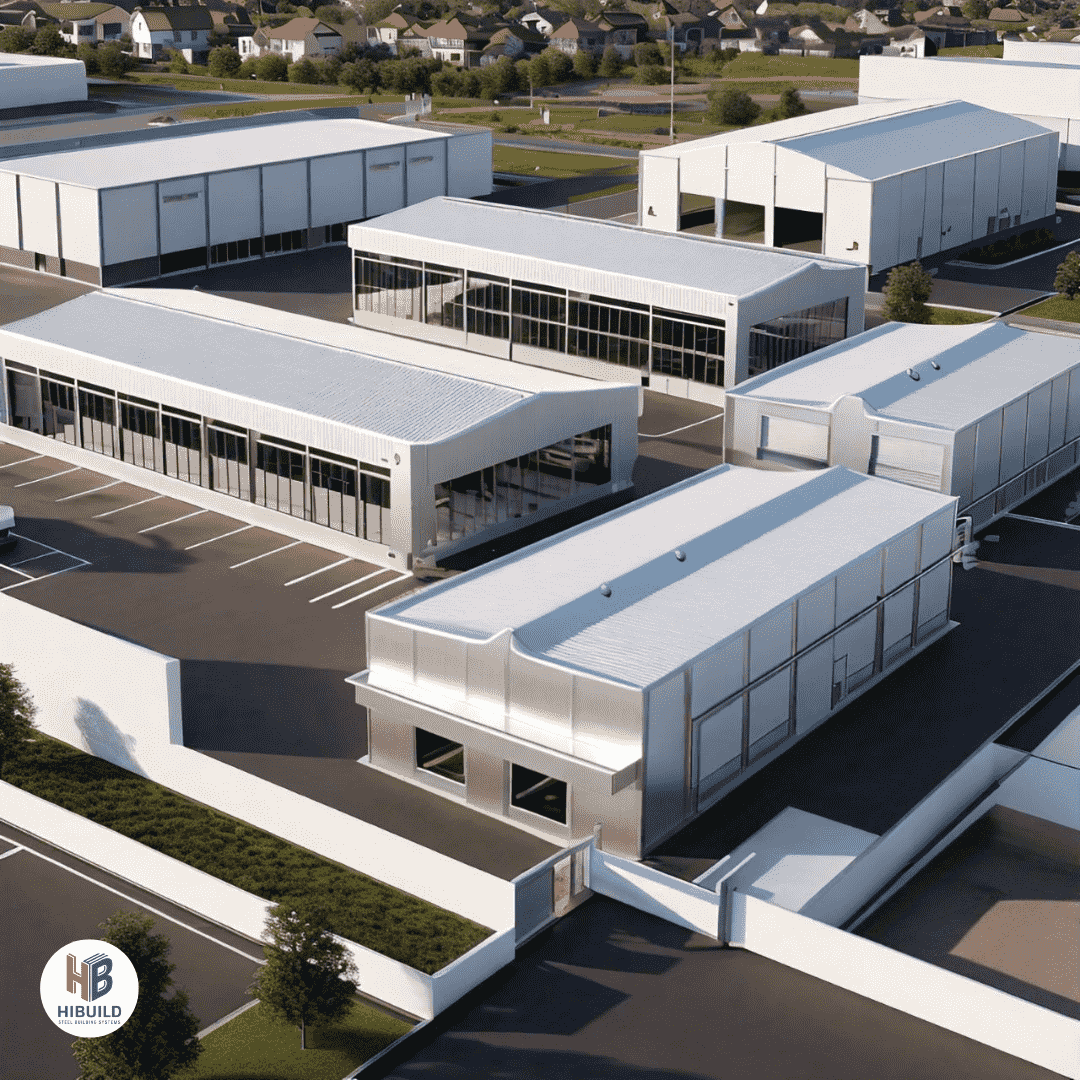

ACCO Engineering, headquartered in Lahore, Pakistan, is a trusted name in industrial, commercial, and structural engineering solutions. With decades of experience in Pre-Engineered Buildings (PEBs), steel structures, and turnkey industrial projects, ACCO has become one of Pakistan’s leading construction companies specializing in design, fabrication, and erection of PEB structures.

Our team combines innovative engineering, international standards, and cost-effective solutions to deliver durable, energy-efficient, and fast-track projects for factories, warehouses, and commercial complexes across Pakistan.

🏗️ Topic Introduction: What Are Pre-Engineered Buildings (PEBs)?

Pre-Engineered Buildings (PEBs) are modern construction systems where the structural components—columns, rafters, and beams—are designed, fabricated, and assembled at a factory, then erected on-site using bolts and nuts.

This method is faster, more economical, and more sustainable than conventional concrete or brick construction.

In Pakistan’s growing industrial and commercial sectors, the demand for PEB solutions is increasing rapidly due to:

- Rising construction costs

- Shorter project deadlines

- A shift toward energy-efficient and sustainable designs

🇵🇰 Why Pre-Engineered Buildings Are Important in Pakistan

Pakistan’s construction industry faces challenges such as delayed timelines, rising material costs, and labor shortages. Pre-engineered steel structures provide a smart, efficient, and cost-controlled alternative to traditional methods.

Key Industry Insights:

- The PEB market in Pakistan has grown by over 35% in the last five years.

- Major industries—textile, pharmaceuticals, logistics, and manufacturing—now prefer steel buildings for new developments.

- Government incentives for industrial zones and SEZs have further boosted the adoption of PEB technology.

🧱 Complete Guide to Pre-Engineered Buildings in Pakistan

🔹 1. Design & Engineering

PEBs start with customized 3D design models, created using advanced tools like STAAD Pro and Tekla Structures.

- Structural loads are analyzed

- Layouts are optimized for function and cost

- Every member is pre-cut and pre-drilled in the factory

ACCO Engineering designs all PEBs according to American Institute of Steel Construction (AISC) and MBMA standards, ensuring durability and precision.

🔹 2. Fabrication

All steel components—primary frames, secondary members, and panels—are fabricated at ACCO’s manufacturing facility in Lahore.

This ensures:

- Zero onsite cutting/welding

- Precise dimensions

- Quality consistency

- Reduced wastage

🔹 3. Delivery & Erection

After fabrication, materials are transported to the site and assembled using high-strength bolts.

ACCO’s specialized erection teams ensure fast, safe, and weather-proof installation, minimizing downtime and project delays.

🔹 4. Cladding & Finishing

PEBs can be finished with:

- Color-coated steel sheets

- Insulated sandwich panels (PUF/Rockwool)

- Aluminum composite panels for aesthetics

Optional features include skylights, ventilation systems, mezzanine floors, and solar-ready roofing.

🏭 Key Features of Pre-Engineered Buildings

| Feature | Description |

|---|---|

| Speed | Construction is 40–60% faster than conventional methods |

| Cost | Up to 30% cheaper due to reduced labor and material wastage |

| Flexibility | Expandable design allows easy future modifications |

| Durability | Designed for high load and seismic resistance |

| Sustainability | Recyclable steel, minimal site disruption |

🌿 Sustainability and Energy Efficiency in PEBs

Modern clients are increasingly focused on green building standards.

PEBs offer:

- Energy-efficient insulation reducing HVAC load

- Natural lighting through skylights

- Solar panel integration on steel roofs

- Recyclable steel materials reducing carbon footprint

ACCO Engineering incorporates LEED-compliant designs and energy modeling to make every project environmentally responsible.

💰 Cost Comparison: PEB vs Traditional Construction

| Parameter | PEB Construction | RCC/Brick Construction |

|---|---|---|

| Construction Time | 4–6 months | 12–18 months |

| Cost per sq. ft. | Rs. 2,500–3,500 | Rs. 4,000–5,000 |

| Maintenance | Minimal | High |

| Flexibility | Easily expandable | Limited |

| Recyclability | 95% recyclable | Non-recyclable |

⚙️ Applications of Pre-Engineered Buildings in Pakistan

PEBs are widely used in:

🏭 Industrial Sheds

🏢 Warehouses & Logistics Centers

🏬 Shopping Plazas

🏗️ Factories & Workshops

🚚 Cold Storage Facilities

🏫 Educational & Healthcare Facilities

🏘️ Residential & Farmhouses

✅ Pros of Pre-Engineered Buildings

- 🕒 Faster Completion: 50% quicker than traditional projects

- 💸 Cost Savings: Reduced material waste and labor costs

- ⚙️ Precision Engineering: Computer-aided manufacturing

- 🌿 Eco-Friendly: Reusable steel and energy-efficient design

- 🔧 Easy Maintenance: Minimal repairs over lifetime

- 🧱 Customizable: Design flexibility for all industries

⚠️ Cons of Pre-Engineered Buildings

- 🔩 Initial Investment: May be higher than small-scale concrete structures

- 🧰 Specialized Fabrication Needed: Requires skilled manufacturing

- 🌡️ Thermal Conductivity: Needs insulation in extreme climates

Despite these, the long-term operational and maintenance savings make PEBs a superior choice for most applications.

❓ Frequently Asked Questions (FAQs)

1. What is the lifespan of a Pre-Engineered Building?

A well-maintained PEB can last 40–50 years, with minimal maintenance required.

2. Are PEBs suitable for multi-story buildings?

Yes, modern PEB technology allows construction up to 5–6 stories, depending on design and load.

3. How long does it take to complete a PEB project?

A typical industrial shed (20,000 sq. ft.) can be completed in 4–6 months.

4. Is PEB construction cheaper than RCC?

Yes. PEBs generally cost 25–30% less than RCC buildings due to reduced material and labor usage.

5. Can PEBs be relocated?

Yes, since structures are bolted, they can be dismantled and reassembled at a new site.

🏁 Final Verdict

Pre-Engineered Buildings (PEBs) are revolutionizing the way Pakistan builds.

They combine speed, strength, flexibility, and sustainability — all essential for today’s fast-growing industrial and commercial sectors.

Whether you’re planning a factory, warehouse, or commercial complex, ACCO Engineering provides end-to-end turnkey solutions — from design and fabrication to erection and finishing — ensuring quality and efficiency at every stage.

🔗 Internal Links

Explore more related pages on our website:

- House Construction in DHA Lahore

- Commercial Plaza Builders Lahore

- Industrial Shed Construction Services

🌐 External References

- Construction.gov.pk – Pakistan Construction Industry Data

- ArchDaily – PEB Design Inspirations

- DAWN News – Growth of Steel Construction in Pakistan

📞 Call to Action (CTA)

Ready to build your next industrial, commercial, or warehouse project with unmatched quality?

👉 Contact ACCO Engineering today for a free consultation!

📍 Office: 3rd Floor, Bigcity Plaza, Gulberg-III, Lahore

📞 Phone: +92 311 1749849

💬 WhatsApp: Chat Now

🌐 Website: www.accoengineering.com

This Post Has 0 Comments